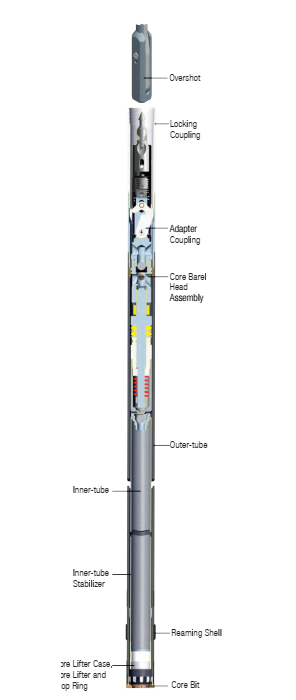

The Overshot is dropped or pushed into the drill string to bring back the

inner – tube assembly by means of wireline cable hoist

The Locking Coupling attaches the drill string to the outer – tube assembly

and maintain a mating surface which the head assembly latches ride

against while performing the drilling.

Besides this, locking couplings maintains directional control for the core

barrel assembly by means of wear resistant preserving pads that wear

down against the drill hole wall.

The adapter coupling matches between the locking coupling and core

barrel outer – tube, maintaning the pocket into which the head assembly

secures deploy

The head assembly maintains latching and also evoting spearpoint

mechanism to grant insertion and bringing back of the inner – tube

assembly, a bearing assembly to let on the inner – tube to remain

stationary and avert sample damage while driling, fluid pressure operating

indications and fluid control valves. All head assemblies integrate a shut

off valve assembly which maintains a fluid pressure signal to drill operator,

revealing a full or blocked inner – tube.

The Landing Ring sits in the upper – end of the outer tube and is

recollected by the mating coupling. As the inner tube assembly trips into

drill string the landing shoulder on the Head Assembly collides the Landing

Ring setting the inner tube assembly into drilling position.

The Overshot is dropped or pushed into the drill string to bring back the

inner – tube assembly by means of wireline cable hoist

The inner- tube takes the core sample as performing

progresses. Multiple inner – tubes can be assembled

extensions to get longer core samples.

Installed in the reaming Shell or in mated outer – tube extensions, the

replaceable and reversible inner – tube stabilizer maintains centralizing for

advanced sample recovery and a bearing between the stationary inner –

tube and the rotating outer – tube

The core lifter is a pressed steel, split collar with a tapered body that

matches to a tapered socket in the core lifter case.

In a core breaking operation, the drill string is climbed off bottom and the

core sample starts to slide out of the inner – tube. Grip marks on the inner

surface of the core lifter takes the moving core sample and pull the core

lifter towards the smaller end of the tapered socket in the core lifter case.

The core lifter is compressed against core sample and retainsit after it has

broken, granting retrieval to surface

The core lifter case mates to the inner-tube and houses the core lifter

in a tapered socket which controls movement of the core lifter. As the

drill string is lifted during a core breaking operation, the core lifter case

bottoms out on the inside of the drill bit transferring the pullback load from

the drill string to the core lifter until the core sample breaks.

The stop ring is a compressed steel snap ring devised to seat into a

mating groove, and maintaining the core lifter in the core lifter case

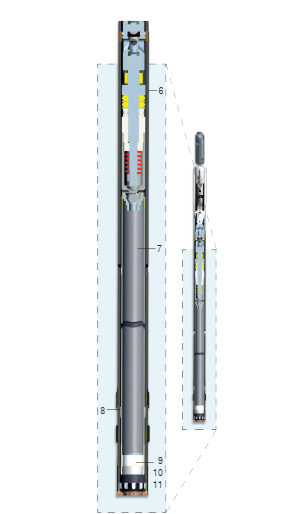

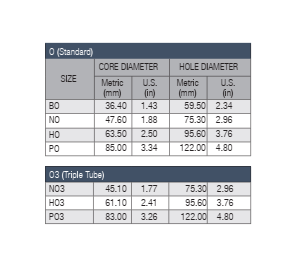

Wireline systems are optimal for use in most drilling conditions and

applicable in standard DCDMA hole sizes. (B,N,H,P)

Son-Mak presently offers two models of the wireline core barrel

system:

O wireline systems, includes the core barrel assembly and the

overshot assembly. Both assemblies are essential to the wireline

system.

The core barrel assembly is formed by the inner-tube assembly and

outer-tube assembly.

The inner-tube assembly is formed:

• Head assembly

• Inner-tube

• Core lifter case

• Core lifter

• Stop ring

The inner-tube assembly takes the core sample during the

performing of the drilling process and seperate of the outer-tube

assembly.

The outer-tube assembly is formed by the remainder of the

core barrels components:

• Locking Coupling

• Adapter Coupling

• Outer-tube

The outer tube assembly always stands at the bottom of the hole

and dwells the inner-tube assembly during the drilling process.

The Overshot is dropped or pushed into the drill string to bring back the

inner – tube assembly by means of wireline cable hoist

The inner- tube takes the core sample as performing

progresses. Multiple inner – tubes can be assembled

extensions to get longer core samples.

Installed in the reaming Shell or in mated outer – tube extensions, the

replaceable and reversible inner – tube stabilizer maintains centralizing for

advanced sample recovery and a bearing between the stationary inner –

tube and the rotating outer – tube

The core lifter is a pressed steel, split collar with a tapered body that

matches to a tapered socket in the core lifter case.

In a core breaking operation, the drill string is climbed off bottom and the

core sample starts to slide out of the inner – tube. Grip marks on the inner

surface of the core lifter takes the moving core sample and pull the core

lifter towards the smaller end of the tapered socket in the core lifter case.

The core lifter is compressed against core sample and retainsit after it has

broken, granting retrieval to surface

The core lifter case mates to the inner-tube and houses the core lifter

in a tapered socket which controls movement of the core lifter. As the

drill string is lifted during a core breaking operation, the core lifter case

bottoms out on the inside of the drill bit transferring the pullback load from

the drill string to the core lifter until the core sample breaks.

The stop ring is a compressed steel snap ring devised to seat into a

mating groove, and maintaining the core lifter in the core lifter case

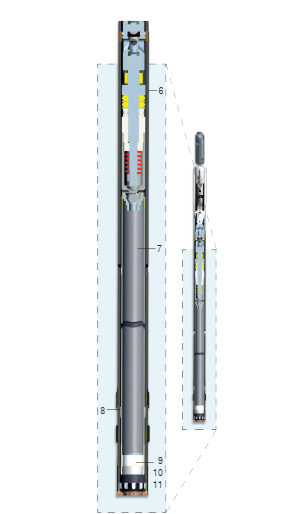

Overview of Structure

Core Barrel Assemblies

The Core Barrel Kits include all elements needed to perform a full core barrel and use it within a rod string:

Head Assembly

Inner – Tube

Stop ring

Core Lifter

Core Lifter Case

Locking Coupling

Adapter Coupling

Landing ring

Outer – tube

Inner – Tube stabilizer

Inner – tube assemblies

Inner – tube assemblies enable the necessary elements to get

a core sample from head assembly to core lifter:

Head Assembly

Inner – Tube

Stop Ring

Core Lifter

Core Lifter Case

Kayapa l. Organize Sanayi Bölgesi Kayapa Sanayi Bulvarı No:4/1 PK.16280

Nilüfer / Bursa – TÜRKIYE

Phone: +90 224 440 0 555

Phone: +90 224 482 44 41

Faks: +90 224 482 44 39

www.son-mak.com.tr

Sign up for newsletter to get updated news and articles about company.

SONMAK © 2024